From Quarry to Building And Construction Website: Checking Out Jaw Crushers for Sale

From Quarry to Building And Construction Website: Checking Out Jaw Crushers for Sale

Blog Article

Successfully Reuse Products With the Power of a Jaw Crusher

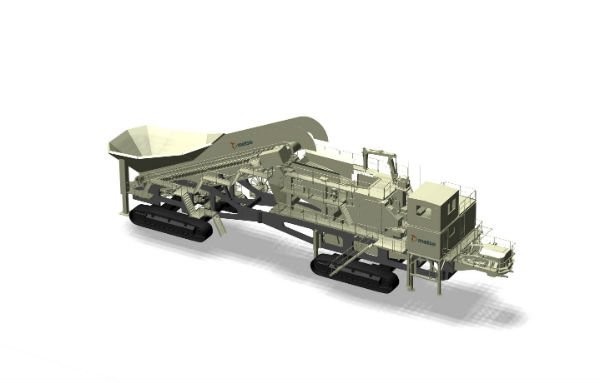

In today's world, the importance of efficient recycling can not be overstated. With the enhancing demand for sustainable methods, markets are regularly looking for ingenious options to lessen waste and maximize source application. One such remedy is the application of a jaw crusher, an effective maker that has transformed the reusing procedure. This interesting tool supplies countless advantages, from its capability to crush a broad range of products to its possibility in improving recycling operations. It is not simply about the power of the jaw crusher; there are several various other elements to consider to ensure a successful recycling procedure. In this discussion, we will explore the benefits of a jaw crusher, the products ideal for crushing, the factors to consider for recycling procedures, and useful maintenance and security tips. So, allow us check out just how a jaw crusher can play a critical role in effectively recycling materials (jaw crushers for sale).

Advantages of a Jaw Crusher

The advantages of a jaw crusher are various and make it a crucial tool for reliable recycling of products. Among the major advantages of this equipment is its capability to generate an attire and consistent item dimension. The jaw crusher's style enables big pieces of product to be crushed to a smaller sized size, leading to a more manageable and consistent product. This is specifically beneficial in recycling applications, where the objective is to generate regular material for reuse.

An additional benefit of a jaw crusher is its high capability. jaw crushers for sale. These equipments are created to manage large amounts of material, enabling efficient handling and enhanced performance. This is specifically crucial in recycling procedures, where big amounts of material need to be processed promptly

Materials Appropriate for Squashing

Different materials appropriate for squashing in a jaw crusher, depending on their physical properties and composition. Jaw crushers are flexible devices that are generally used in demolition, mining, and construction markets to crush materials into smaller sizes. One of the key consider identifying the suitability of a product for crushing is its solidity. Harder products such as basalt, quartz, and granite are often crushed in jaw crushers due to their high compressive stamina. These products can stand up to the stress put in by the jaws of the crusher, leading to reliable crushing.

An additional crucial consideration is the abrasiveness of the product. Materials such as dolomite, sandstone, and limestone are known to be unpleasant and can trigger too much wear on the jaws of the crusher. With correct upkeep and the use of wear-resistant products for the jaw plates, these products can still be effectively crushed.

Additionally, the dimension and form of the material additionally contribute in determining its suitability for crushing. Jaw crushers are particularly reliable in crushing huge, hard, and irregularly shaped materials. They may not be as efficient in crushing smaller, softer, and more consistent products.

Recycling Procedure Factors To Consider

This will certainly identify the size and capability requirements of the jaw crusher that will certainly be utilized in the reusing operation. Various crushers have different capacities in terms of minimizing materials to a details size array. Comprehending the end item requirements is essential in choosing the suitable jaw crusher for the reusing operation.

Another vital consideration is the functional cost of the recycling procedure. This consists of the cost of keeping the jaw and acquiring crusher, in addition to the price of power and other resources needed for its procedure. It is essential to pick a jaw crusher that provides high effectiveness and low operating expense to make certain the success of the reusing procedure.

Upkeep and Security Tips

Taking into consideration the essential nature of upkeep and safety in a reusing procedure, it is necessary to apply effective strategies to make certain the smooth performance of the jaw crusher and secure the well-being of personnel involved. Regular maintenance is important for the jaw crusher to operate at its peak efficiency. This includes inspecting the equipment frequently, inspecting for any kind of indications of damage, and addressing any problems immediately. Lubrication is additionally important to prevent friction and overheating, so it is necessary to comply with the maker's standards for oiling and oiling the maker. jaw crushers for sale.

Additionally, safety and security preventative measures have to be purely abided by in order to avoid injuries and crashes. All personnel running the jaw crusher need to obtain appropriate training on its usage and security treatments. Protective equipment, such as hard hats, safety and security glasses, and ear defense, must be worn at all times. The job location ought to be kept tidy and complimentary of particles, and any kind of potential risks should be resolved promptly.

Routine examinations and maintenance timetables ought to be developed to make sure that the jaw crusher is functioning efficiently and securely. By complying with these upkeep and safety ideas, recycling procedures can maximize the effectiveness of their jaw crushers while focusing on the wellness of their workers.

Taking Full Advantage Of Effectiveness With a Jaw Crusher

It is important to match the jaw crusher's capacities to the certain requirements of the product being processed. Monitoring the crusher's efficiency through routine dimensions and data analysis can aid determine opportunities for enhancement and optimize the crusher's procedure. By implementing these approaches and methods, my response operators can make best use of the effectiveness of a jaw crusher and attain better general productivity in their recycling operations.

Conclusion

In this conversation, we will dig right into the benefits of a jaw crusher, the products suitable for crushing, the factors to consider for reusing operations, and useful upkeep and safety suggestions. Let us check out just how a jaw crusher can play an essential duty in successfully reusing products.

Keeping track of the crusher's performance via normal measurements and data analysis can assist recognize possibilities for improvement and maximize the crusher's operation.In final thought, a jaw crusher uses countless advantages in efficiently recycling materials. In general, the usage our website of a jaw crusher shows to be an efficient option for reusing products.

Report this page